With the joint efforts of Dalian University of Technology School of Chemical Engineering, Zhongshan Zhi'an Chemical Technology Co., Ltd., and Zhongshan Micro-Reverse (Suzhou) Technology Center, a number of innovative technologies were adopted. The headache problem of nitrification reaction was solved by silicon carbide reactor combined and 3D printing nickel-based alloy reactor, which helped the largest pesticide company to solve the problem of nitrification synthesis, and completed the pilot test of the nitrification reaction in April 2021 without any difference. It is expected that in the fourth quarter of 2021, the 20,000m3/year nitrification microreactor and continuous oxidation synthesis equipment will be put into operation.

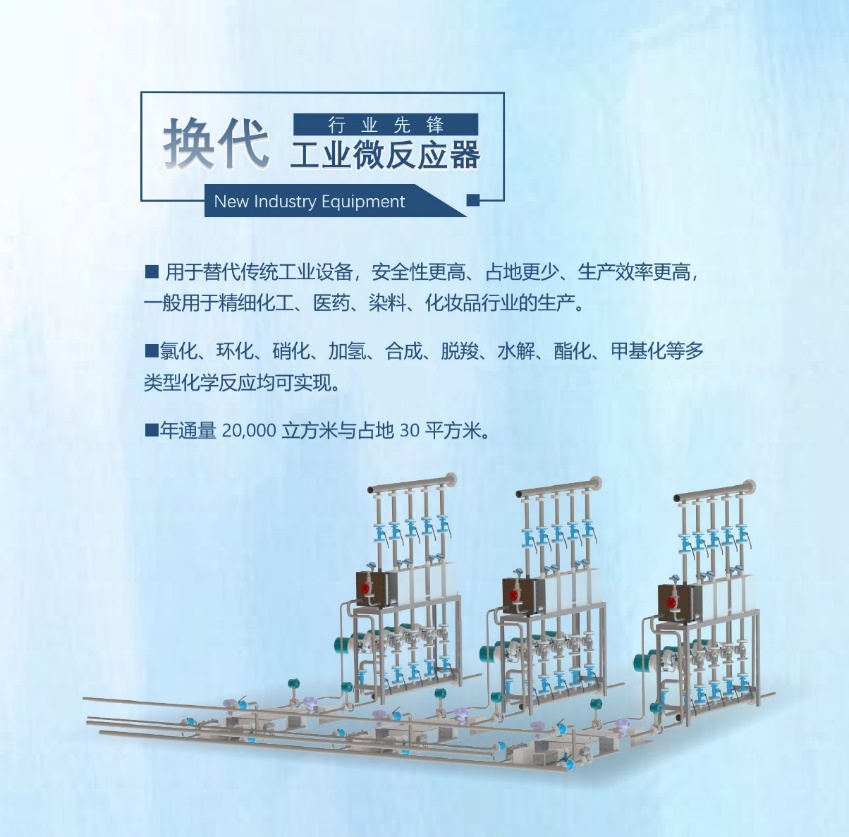

The innovations of this project include: while achieving a flux of 20,000m3, the number of reactor modules is reduced to five. The liquid holding capacity of a single micro-reactor exceeds 2 liters. The combination of 3D-printed corrosion-resistant alloy turbulent flow channels and silicon carbide flow channels is perfectly reflected the advantages of the microreactor.

The enterprise is designed according to high standards. The control system is 250 meters away from the production workshop. The central control DCS and SIS systems are adopted, which through flow ratio, temperature chain, pressure chain, and data comparison, remote production operations can be reliably implemented.

It is easy to use microchannels for milliliter-scale experiments, but to achieve amplification of 200-500 times, many conditions that are not conducive to the reaction will be encountered, such as parallel connection, series flow, and short circuit. When the pilot scale is enlarged by 10-50 times, the inconsistency of the temperature flow field and the reactant flow field will be encountered.

The using of equal surface area flow channel technology overcomes the nitrification reaction and successfully solves the following problems:

1. Large heat release and corrosion problems;

2. Control of by-products and impurities;

3. The problem of product crystallization blocking;

4. The process control point is adjustable and controllable;

5. Low investment cost and short return period.

Microreactors are used in production, which requires engineering optimization and avoids the pitfalls of various materials. The micro-reaction design leading by Zhongshan Micro-Reaction is based on listening to and absorbing the experience of cooperative units, and according to the process characteristics and difficulties, individual design and versatility are taken into account, and the smallest investment is maximized.

The design of the microreactor in this project is quasi-universal and specific, and can be compatible with other reactions. It has the following characteristics: firstly, the 3D printed corrosion-resistant microreactor is designed to withstand a pressure of 10MPa. Secondly, a silicon carbide microreactor designed to withstand a pressure of 4.5MPa. Thirdly, the reaction flux, reaction temperature, and reaction residence time can be adjusted in a large range.

In order to achieve high yield and precise proportioning, the metering pump of the feeding system does not use an imported pump, but adopts the ZSMR patented cam metering pump. The pump has the following characteristics:

(1) The pump flowing range is 1-15L/min. No compensation is required within 2MPa. The flowing rate and the speed of the servo motor are fixed values, which is convenient for accurate flow adjustment.

(2) The pump outlet pulsates 1%-3%, so the feeding system does not need to be equipped with a damper.

(3) The instantaneous flow ratio of materials A and B can be controlled within 0.2% fluctuation.